200 meters of thread over many weeks

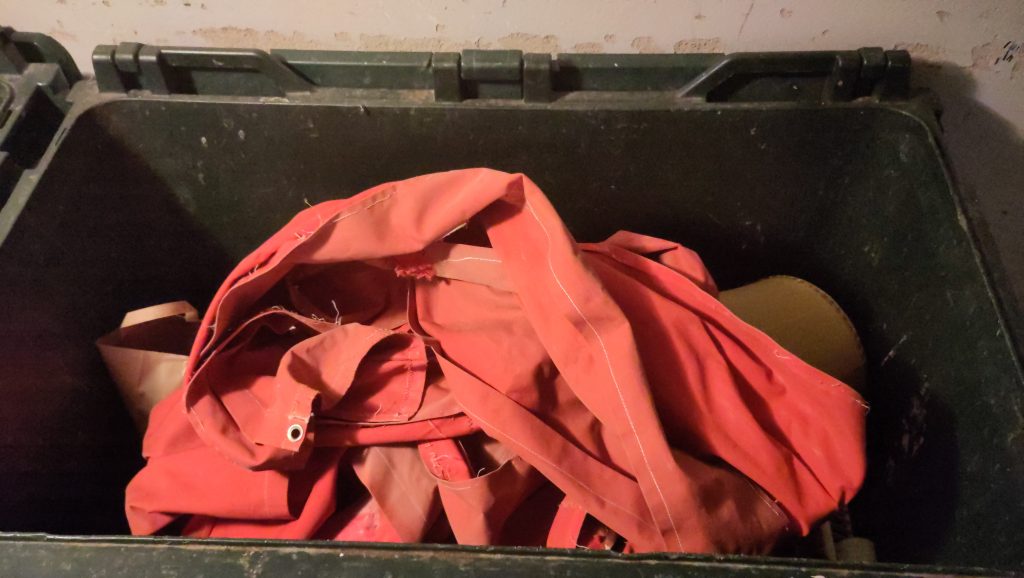

The old canvas covers for the sails on Aquabelle had seen their best days, and it was high time to make new ones. Already the summer I bought her I needed to repair seems here and there and put in patches. The covers used to be red but more and more resembled wine stained bedding, both in colour and in texture. The makers mark was from a company that was bought up in 2006, almost 20 years ago.

New covers costs a lot of money, especially the cover for the roller furling headsail, something I have now come to understand why, so of course I decided to do it myself. I had previously had sewn the companionway dittystow which proved that my sewing machine should be able to handle it. In the end I probably should have had a bigger machine, it now needs service.

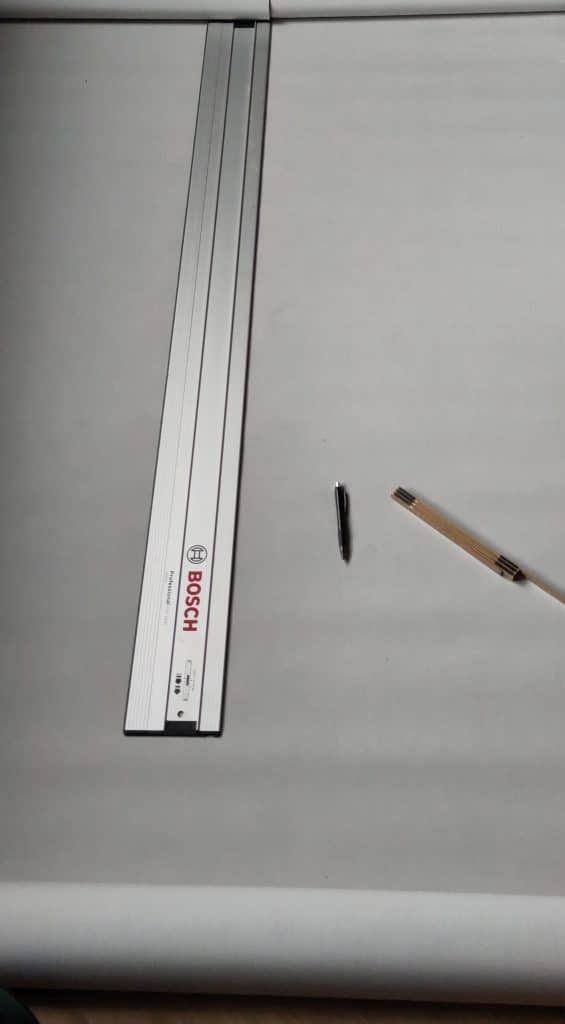

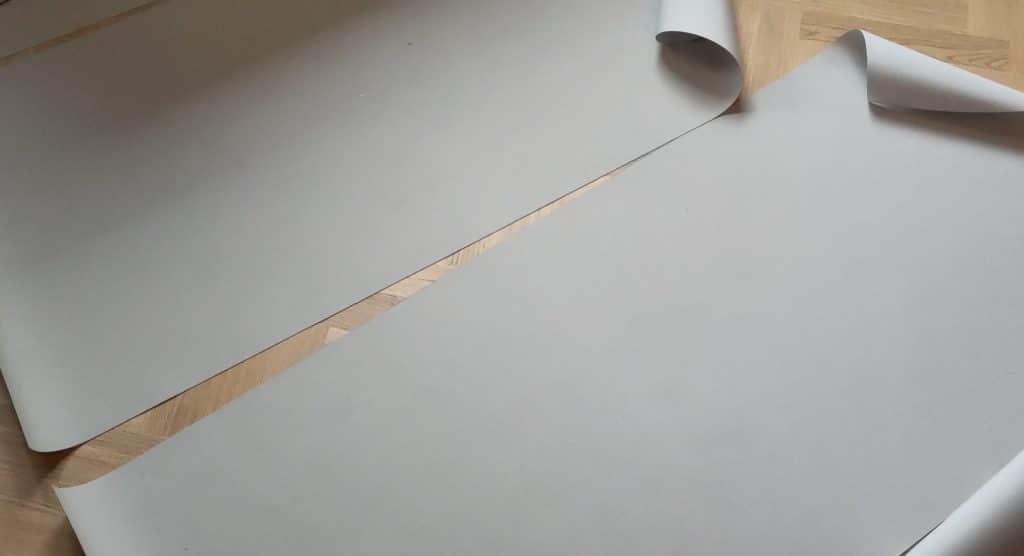

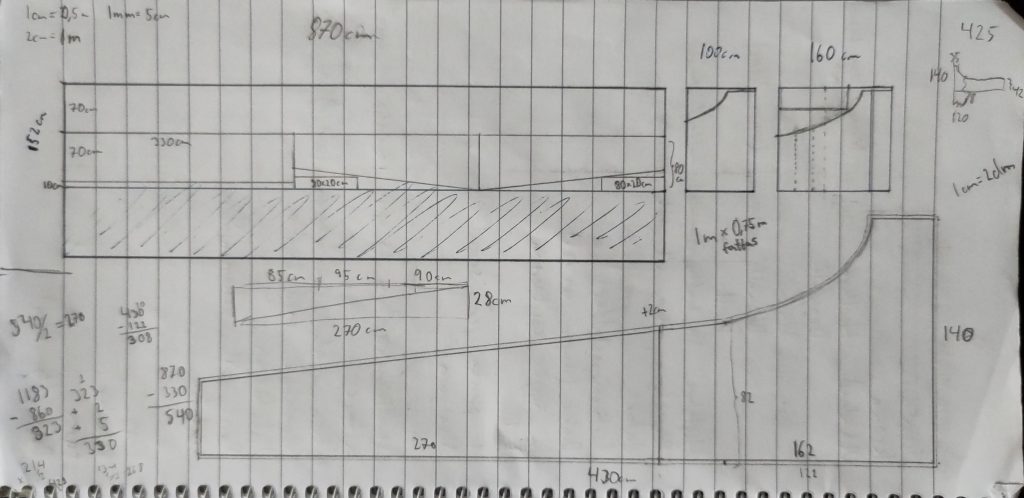

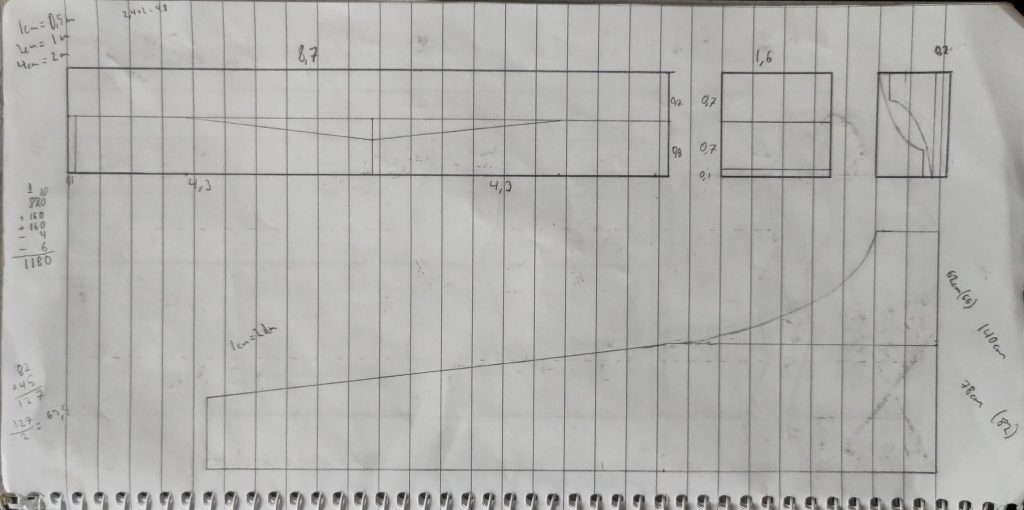

Anyhow, I found some left over canvas stock from a bankrupcy which I bought. Problem was that it was in three pieces (8.7, 1.6, and 1 meter long, 152 width) and I wasn’t sure that the amount of fabric was enough. It took some tries on paper to figure everything out and in the end it seemed I would have enough. So I drew the width of the foresail cover on the 8.7 meter piece and started cutting.

Yes, that is a track-saw track I used for the lines, the longest straightest thing I own. WIth the whole 8.7 m length cut I proceeded with the 1.6 m and cut two pieces of that and then joined these three pieces together length-wise to get a tad under 11.9 meters sinceeach seem eat some lenngth on both pieces. Accordning to my measurments of the old one I needed the length to be something like 11.9 on the finished one. I also know that I felt the old one to be a bit short, in the end I added another 30 cm to the new one with another seem.

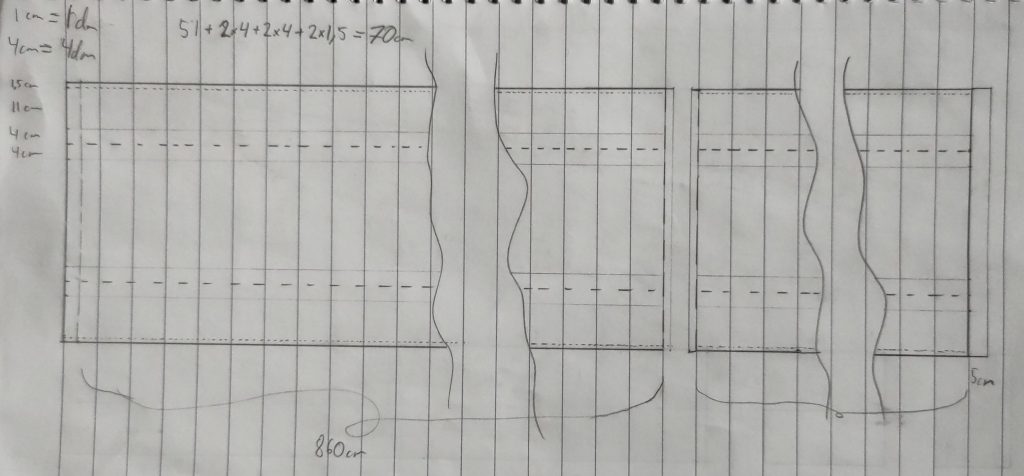

After all the lengths were sewn together I proceeded to fold the entire length while adding pieces of tape to hold it in place. The folds are there to add pieces of plastic with a pulley inside to enable tightening the cover around the sail to avoid flapping and prematurely demise of the fabric. Now I had a manable snail of sorts that could be refined to a sail cover so I decided to switch to the mainsail cover.

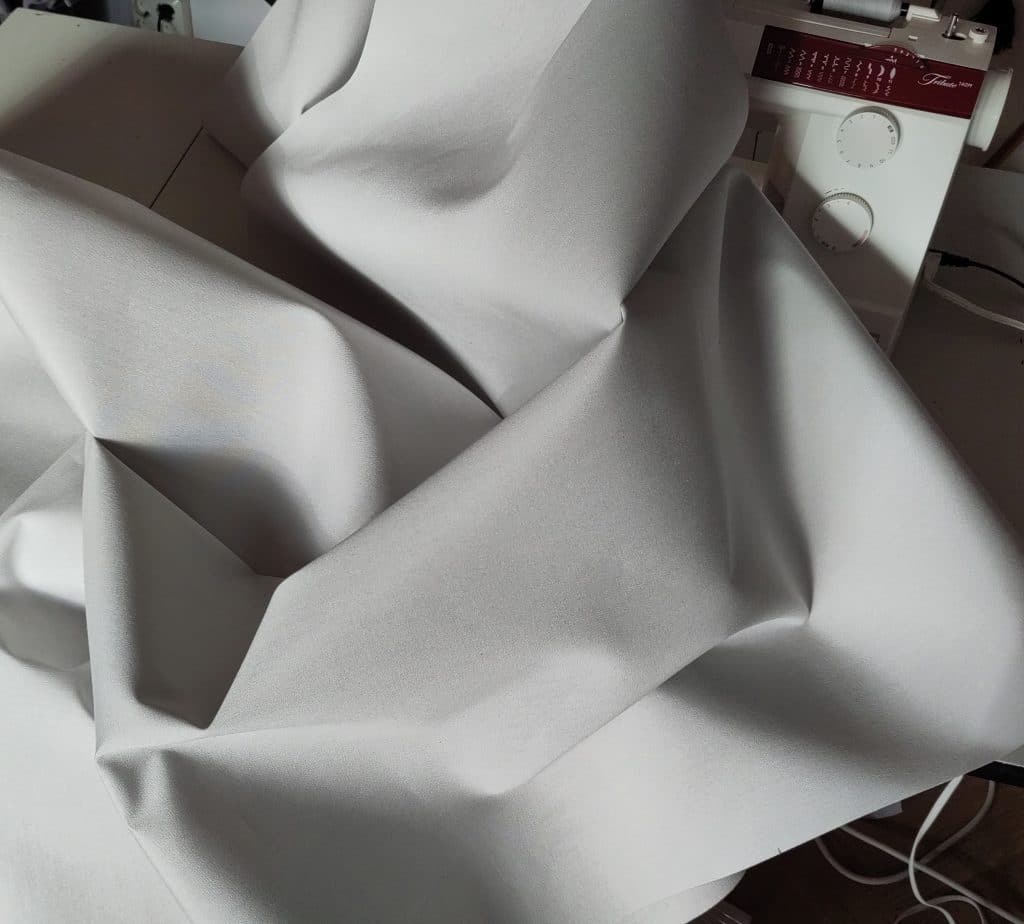

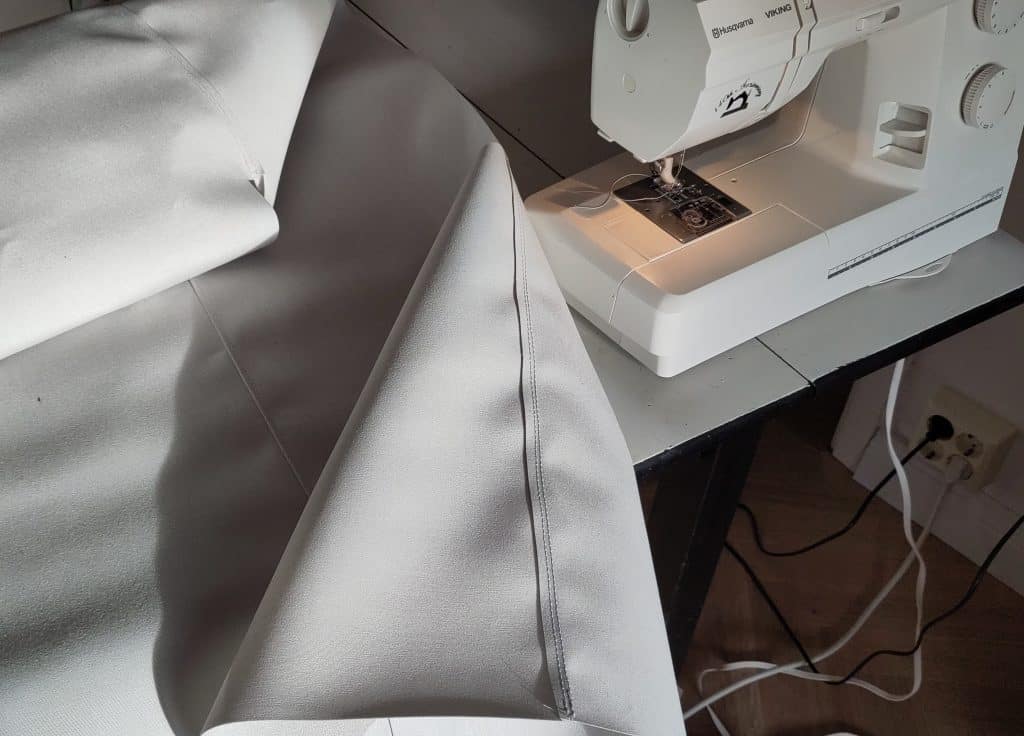

I cut out according to my drawings, first so that the entire sides would be big enough and then so that the two halves would become one piece. I don’t have any pictures of the drwing and cutting, but I have some of the difficulty moving the massive and stiff piece of fabric around on my small sewing machine.

All seems sewing pieces together were sewn right side to right side and then the backside was folded over and another seem was sewn to hold it down on the backside. Almost none of the side were zig-zagged due to there being a polyurethane coating on the back of this kind of fabric which should keep it together. Time will tell if this was a good decision. It should be sufficient to just lightly burn the edges in case they start to fray since the fabric is acryllic.

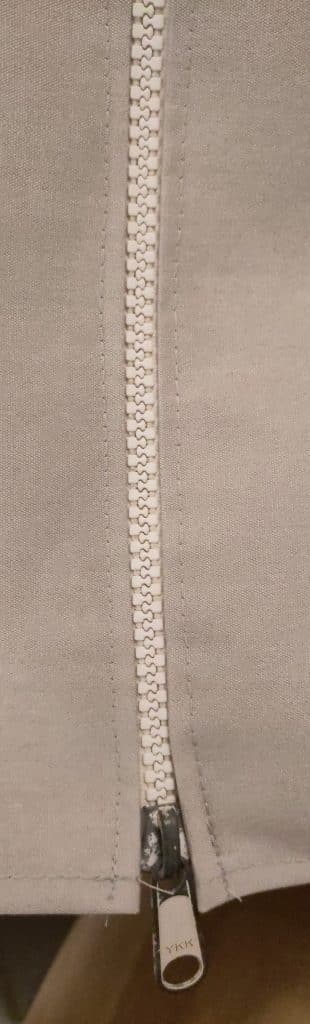

With the basic form created it was only hemming and a zipper left to do. I started with sewing the zipper according to the method I saw on some guides online, i.e. right side to right side, edge to edge, then folding over and sewing another seem to hold the fold down.

I had some headache on how to make sure that the zipper would align between the pieces, but a couple of pieces of double sided tape solved that problem. I think this turned out nice.

After the zipper I hemmed the entire underside by folding the fabric narrowly (1 cm) twice and sewing a seem. I folded the top twice as well, but big enough so that a string could be pulled through in case that is desireable in the future.

For the aft end while hemming, I also added a reinforcement patch on the top in the middle to help the fabric support a grommet (which will be made some time in the future). I made the length of the cover a little bit longer than the old one as well so that the cover wouldn’t need to be stretched as much as the old one. We’ll see how that will work out.

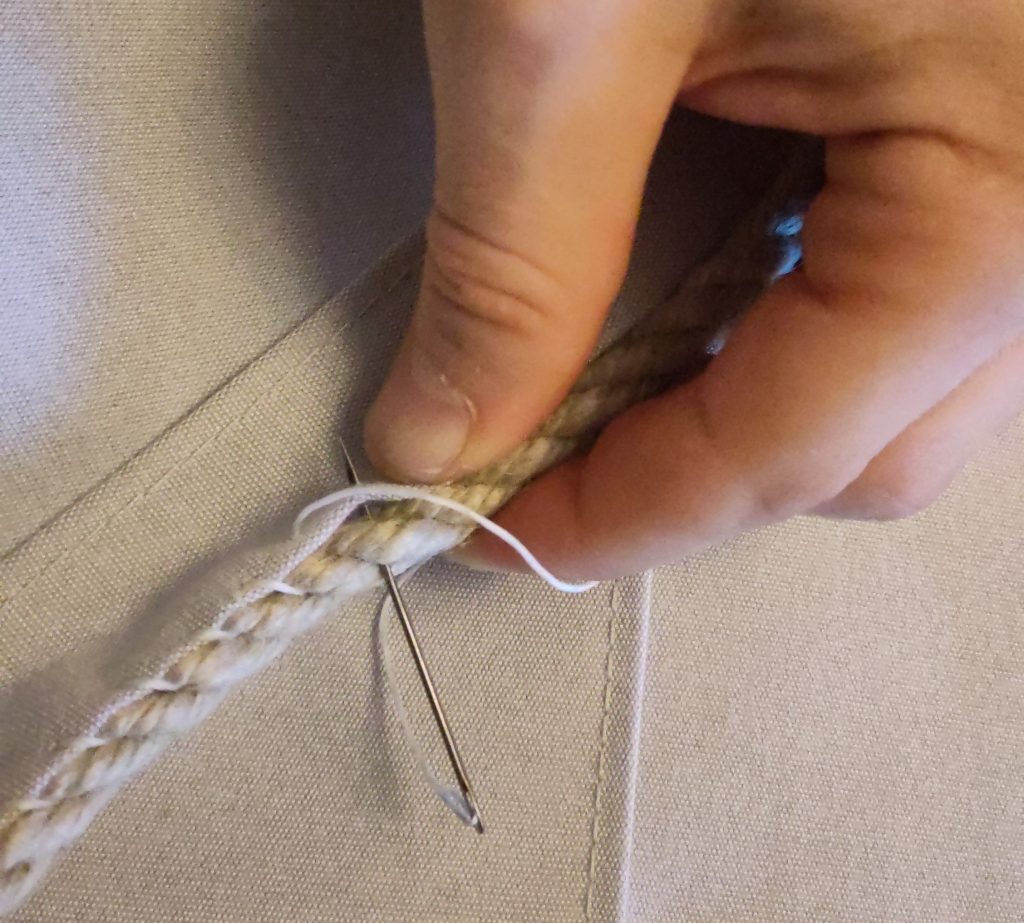

With the basic shape done I now got help from a friend with a couple of hours a weekend so decided that with help I should tackle the really long seems lengthwise on the foresail cover (including the zipper), and to get some help starting to handsewing the plastic things with pulleys in them.

After a couple of weeks hand-sewing all of these plastics pulley-thingies, finding time here and there to add half an hour of sewing or so, I managed to complete all 22 of them. Only one needle died during the process. With all of them done I felt like I had the finish line of working covers in sight and I cracked on with the rest of the work needed one saturday.

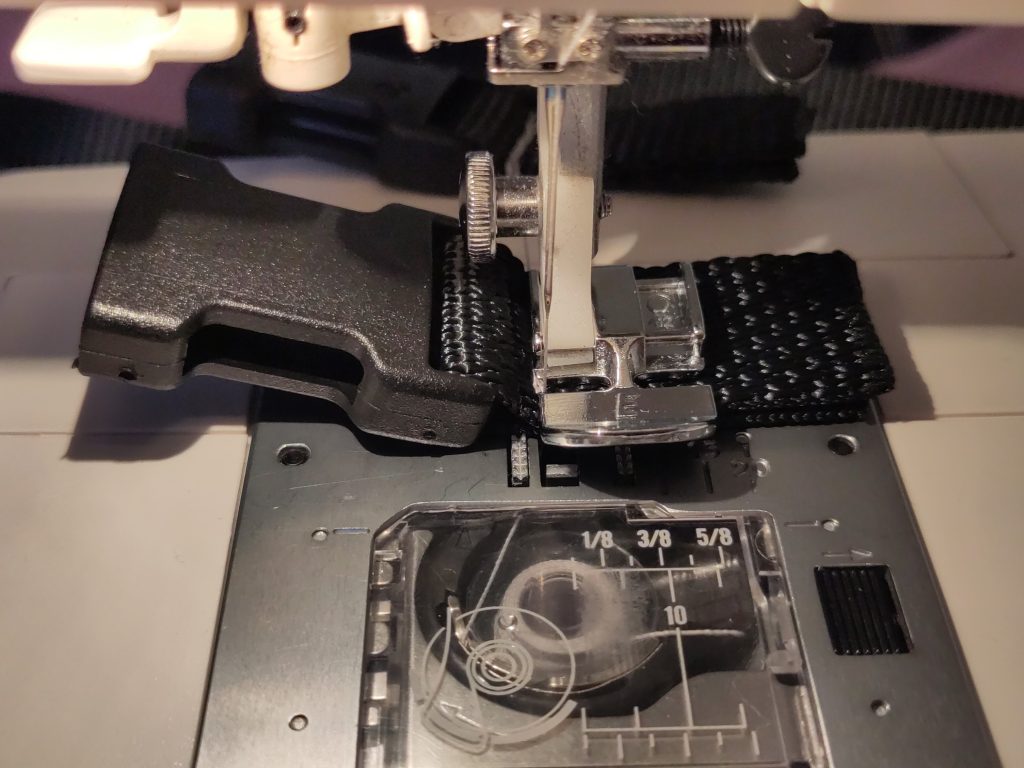

First I finished the top of the foresail cover by adding some reinforcing soft polyester webbing that would both serve to protect the end of the zipper by holding the top together, a hoisting point for the halyard, and a D-ring for the line going through all the plastic pulleys to also pull the head tighter. I spent to long time trying to get a metal grommet through all layers of acryllic fabric and polyester webbing before giving up and doing the grommets the more traditional way with thread. Due to the massacre of trying to get the metal grommet through they look a bit different from each other but they should still work.

The bottom end I did with metal grommets since the thickness is alot thinner and also these will see more line sliding in and out and hence, more abrasion.

For keeping the undersides together and the canvas cover on the boom I decided to add snap-buckles. Six of them were added in quite short manner. The top of the mainsail cover was finished by sewing a piece of fake hemp to it in a traditional way. The plan is to do the same for the undersides, mostly aesthetic, so it will have to wait until a rainy day this summer.

All in all, it has been a much bigger project than usual, which is not unusual, as usual. I now understand why especially good quality, well made headsail canvas covers costs a lot of money. I suspect that with a better sewing machine and not having to cobble together different pieces of fabric to have enough would speed up the process and reduce the required man-hours. A mainsail cover is quite manageable, especially for a smaller boat, but headsail cover with a lot of hand-sewing is not for the faint of heart.

All in all I think the length of all the mechine sewed seems approximate 100 meters in length, which would mean that at least 200 meters of thread has been used in this project. With some confidence in my work, but mostly because I butchered the old covers for parts, I threw the old ones away. Quite satisfying.